Birth of a harness, the Kanibal Race II

The Kanibal Race II is an exceptional harness, designed for high level pilots looking for performance during a world cup stage or a large scale cross country flight.

But such a product doesn't just appear on the market overnight...

It is the result of huge number of hours of reflection, of sewing, of prototypes, of tests both in 3d simulation and in actual flight conditions. It's a whole team that has worked for more than five years to offer you this product.

The first prototypes are actually much older, as shown in this picture of Max in 2009 at the World Cup Superfinal in Italy, with a prototype chassis based on a Kanibal Race!

Inside, the beginnings of the adjustable air damping system that is now in the standard Kanibal Race II.

For the record, the Kanibal Race was on the 1st step of the PWC Super Final, men and women (with Charles CAZAUX and Keiko HIRAKI), and Kortel Design at the 1st place by team!

It is impossible to summarize in a few lines all the stages of the design of this harness, the hours spent circling around a study model to find a solution to this fold, or the ideal placement of a reinforcement.

It is also impossible to make you feel the moments of doubt when a problem (as small as it is!) persists and does not let us see the solution, until the delivery and this famous solution finally revealed!

The technical resolution of a problem can also come from the use of existing components (trims, metal loops, or other), but at Kortel Design, we do not hesitate to design our own fittings and to get them fabricated according to our own specifications, to best meet our needs when manufacturers catalogs do not suit us!

On the Kanibal Race II, no less than 7 components have been developed in-house.

In total, there are more than 640 components (fabric parts, straps, buckles, etc ...) and more than 1300 assembly operations of these elements to obtain the Kanibal Race II and more than 100 hours of assembly.

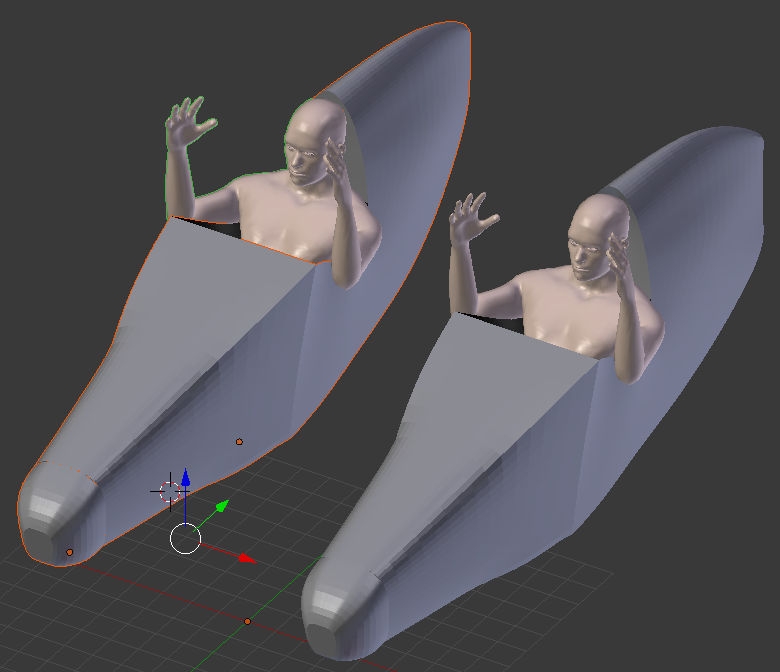

The frame of the harness is its chassis. It seats the pilot with maximum comfort, and gives him control of the wing. It has to transmit all the relevant information for the pilot to sense the airmass, to react with the right movement at the right time. The harness is really the link between the pilot and the wing, and must be able to transform the intent of the pilot into an action on the wing. It is the "active" control in the harness.

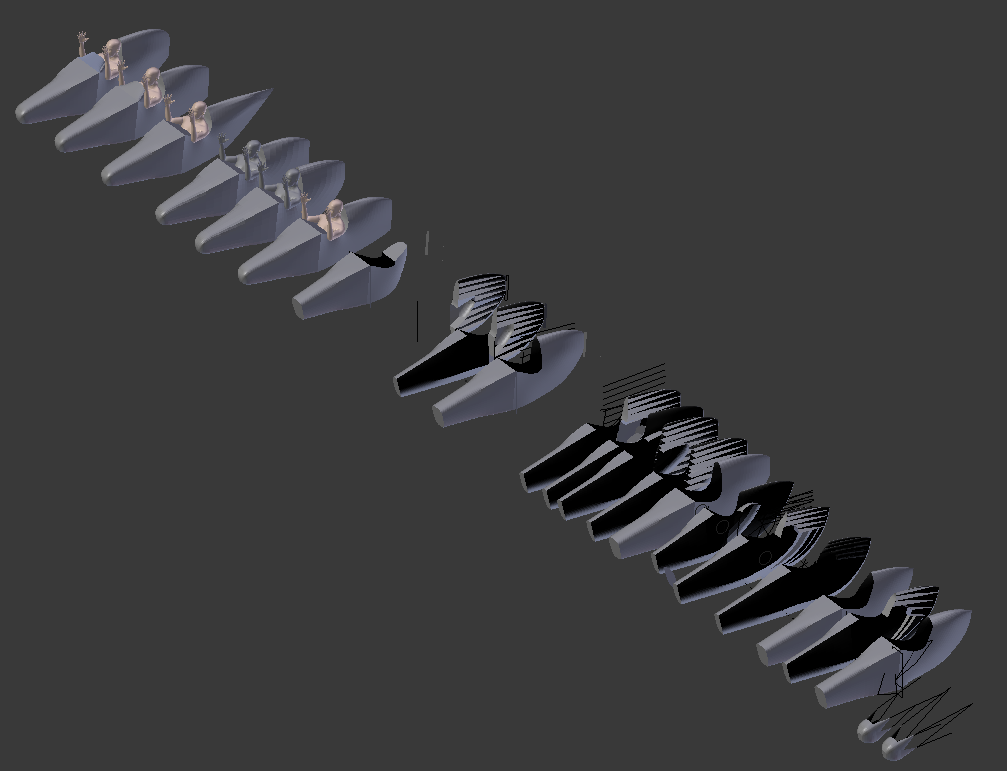

Numerous study chassis have been mounted, tested in gantries (with real pairs of butts in them!), modified, re-tested, re-modified, re-re-tested, re-re-modified, (you get the idea, right? 😉 ) ...

with no less than 22 versions compared!

Once the chassis seems to be suitable (but it can change ...), we attack the design of the trim, that is to say all the external part of the harness including protections, kocon, pockets, profiling, ...

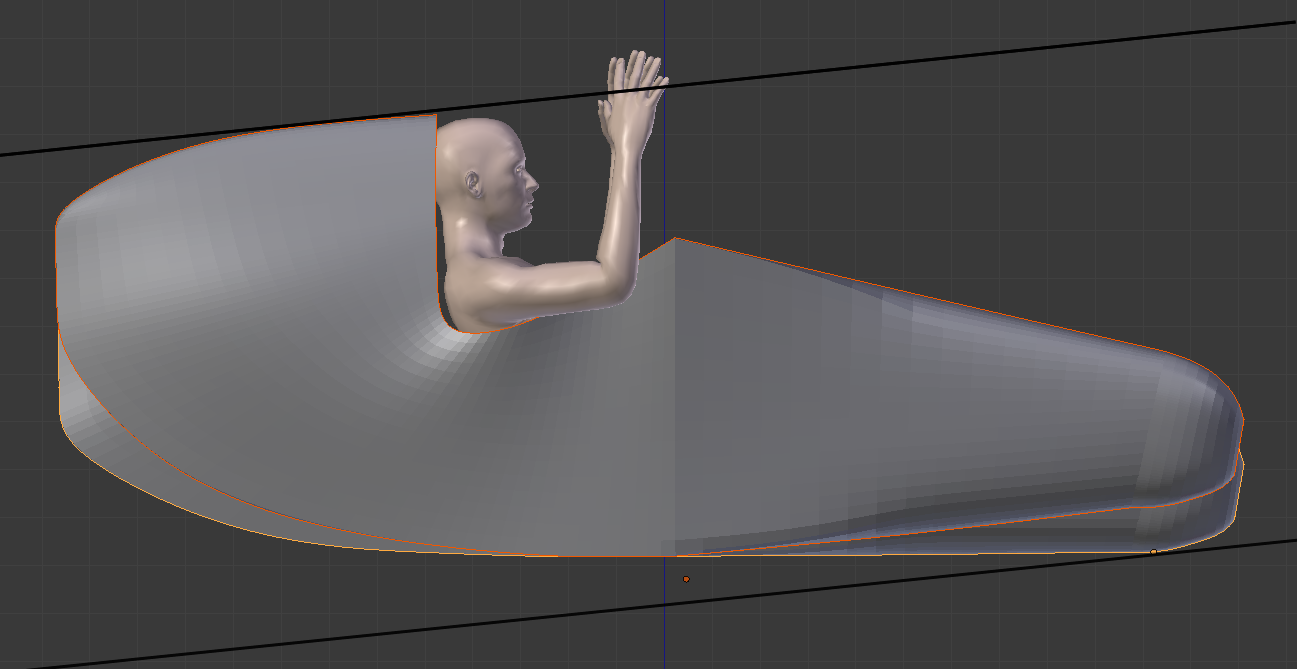

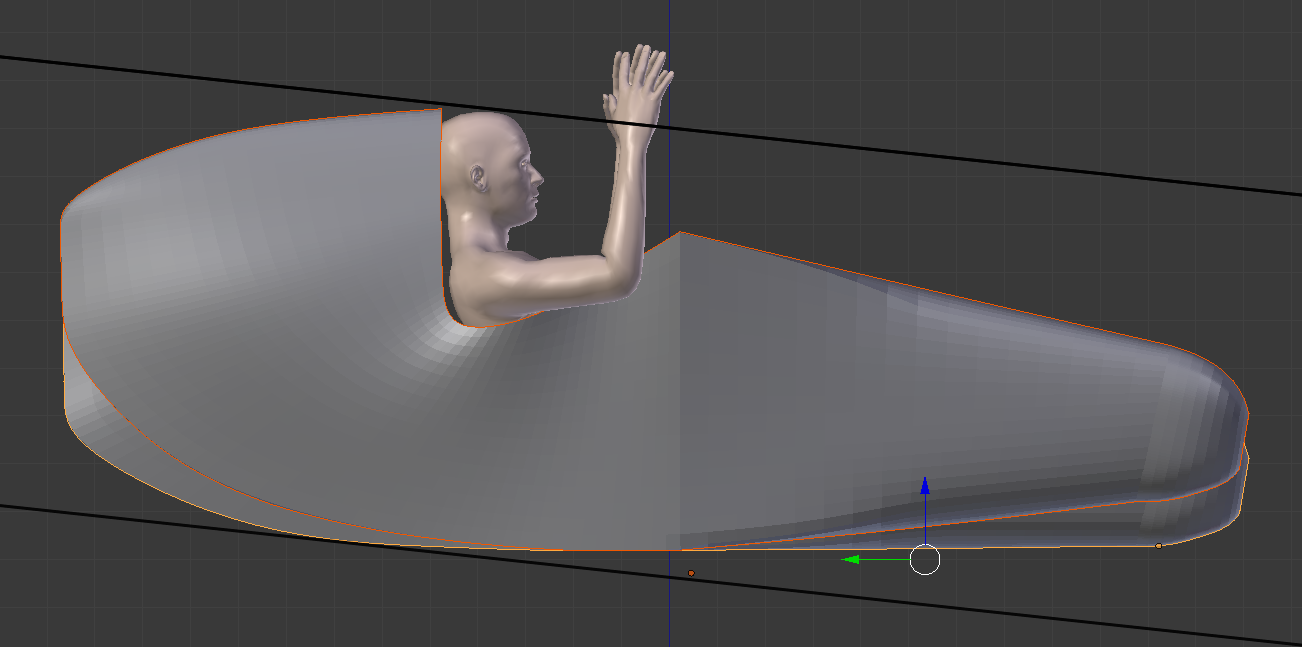

The 3D modeling intervenes then, to optimize the shape of the whole in the various flight configurations.

Over 435 hours of CFD (Computational Fluid Dynamics) calculations in 3d flows were carried out to validate the final form of profiling, in order to obtain not only the lowest drag, but above all the greater tolerance to variation of incidence.

It is very complicated to determine the best profile, because a simulation gives a result only for 1 given position, but it is clear that in reality (in the air) the position constantly changes (incidence, yaw, pitch, roll...) and that a "perfect" profile for one position can prove to be much less efficient for a modified angle of incidence of a few degrees. It is therefore necessary to determine an "optimum" profile, which can not be perfect in all situations, but the best possible in these same configurations.

A lot of work had already been done in 2001 with this article about the aerodynamics of harnesses.

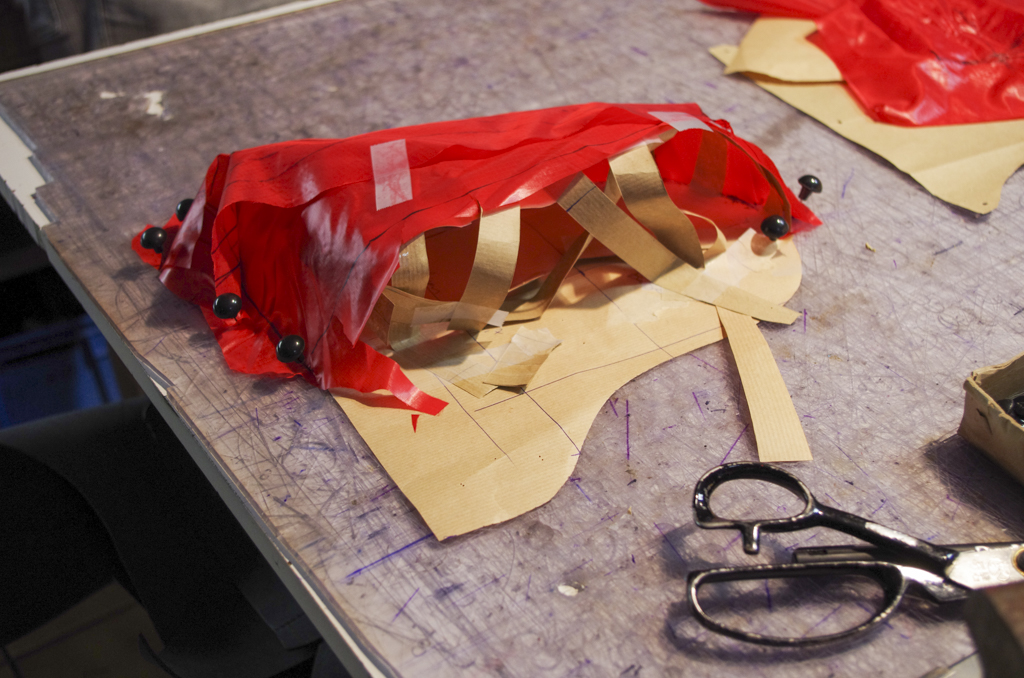

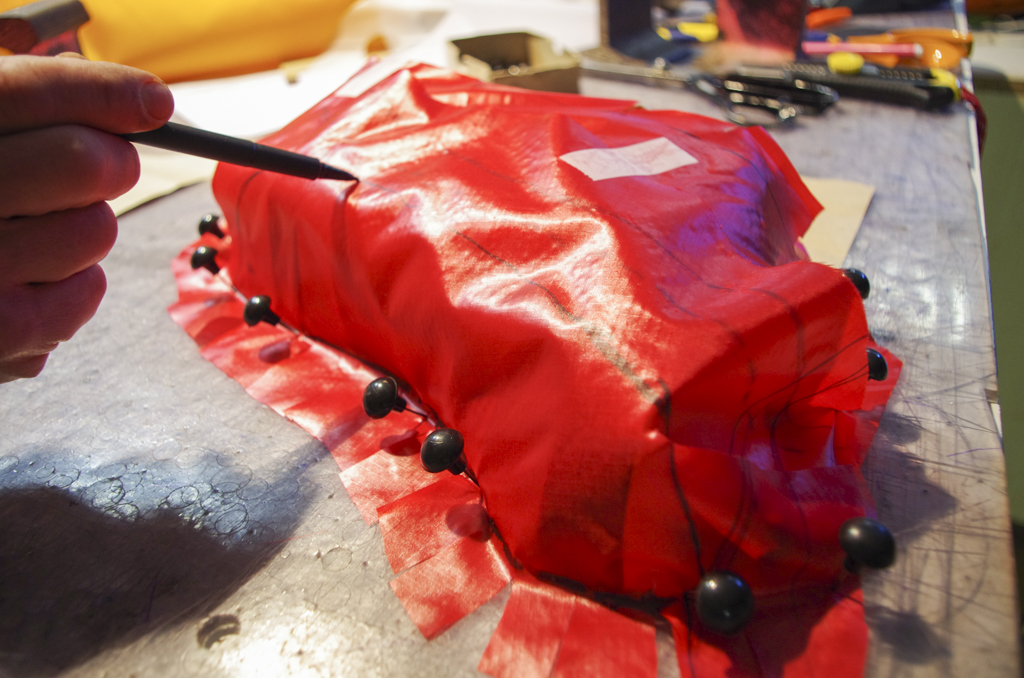

Drawing in 3D on a computer is good, but then you have to make it feasible in sewing!

Numerous study pieces are then made in "molding", to determine the different "flat" parts that will allow once assembled to obtain a 3D shape.

The final assembly of the harness can then begin: frame + trim.

These prototypes allow us to check all the steps, but also to start flying to test in real situation all the technical solutions defined in the office and in the workshop.

18 complete prototypes have been assembled, including 13 flyable models and 5 study models. To know that it is necessary to count approximately 100h of work to assemble a complete flying prototype...

We estimated more than 2000h of realization in workshop for this harness...

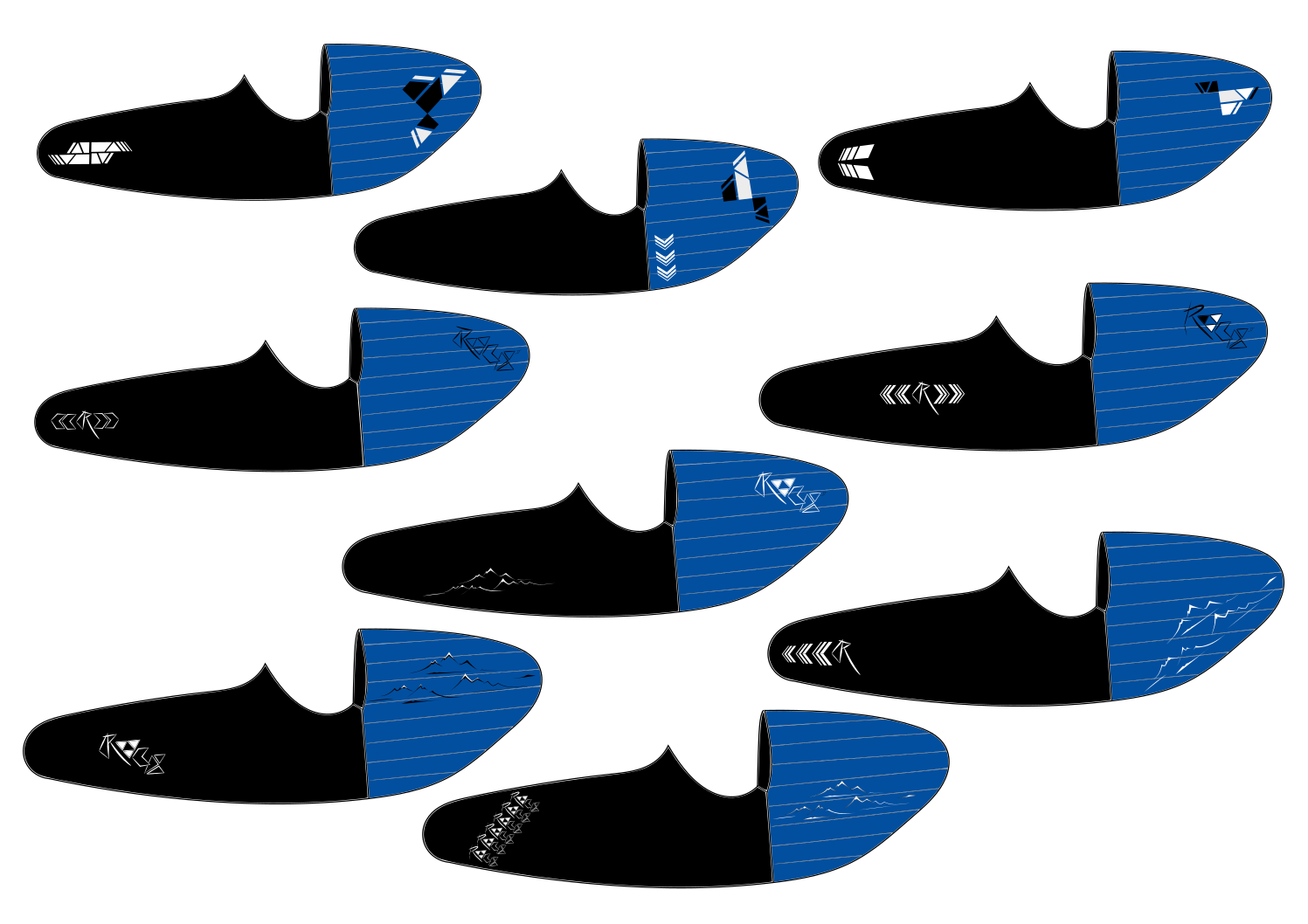

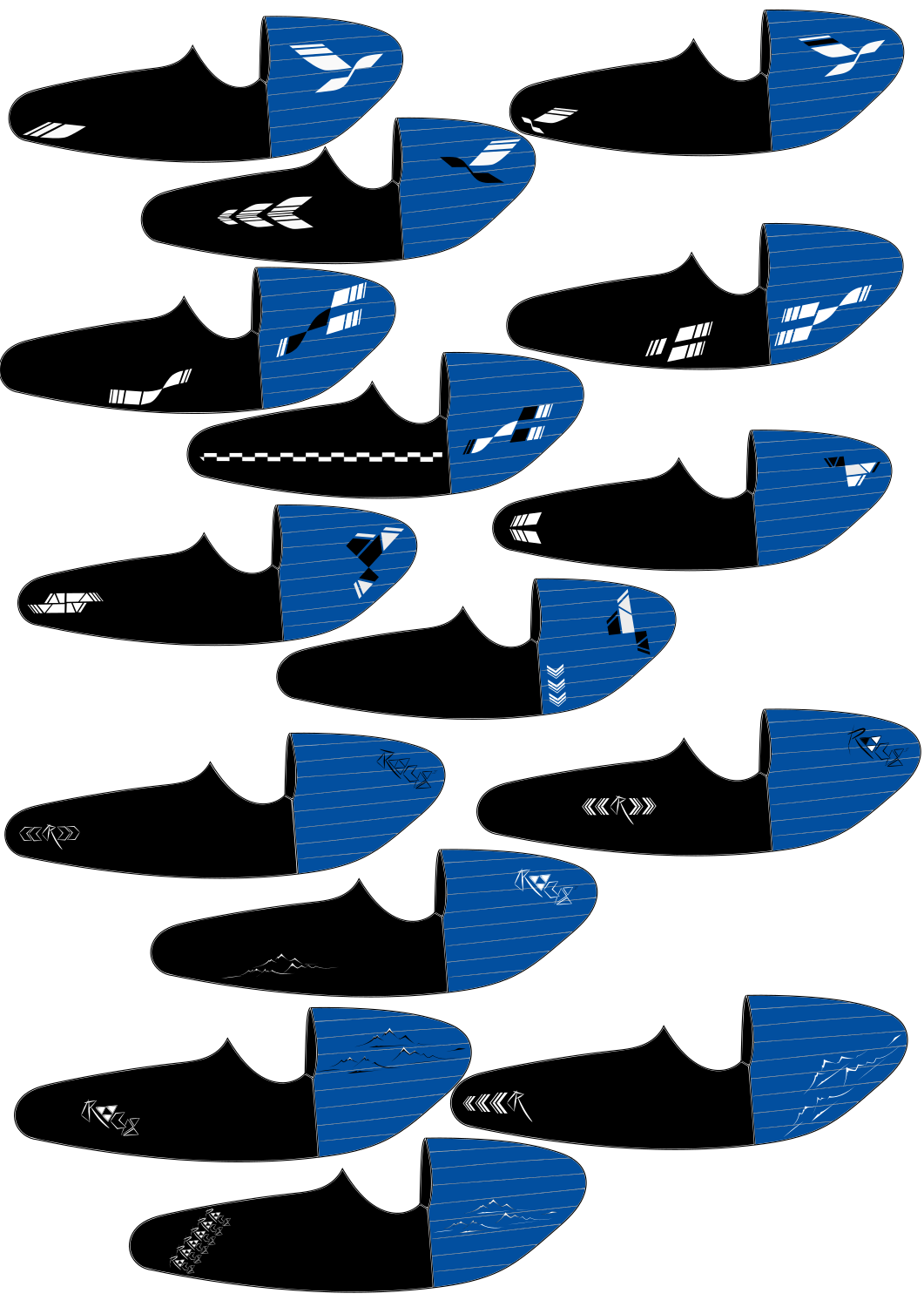

When a final prototype seems to give satisfaction (but it can still change!!!) in all the relevant parameters, the first design sketches begin to emerge to dress the different parts of the harness.

To sum it up, it is a super dedicated team (5 people) who gave it all they could to offer you this exceptional product, and who we are sure will give you the best to reach the best level in the World Cup, or make wonderful cross country flights throughout the world...

Find all the technical specifications on the page dedicated to the Kanibal Race II

The whole team Kortel Design...